CED Compressed Air Blog

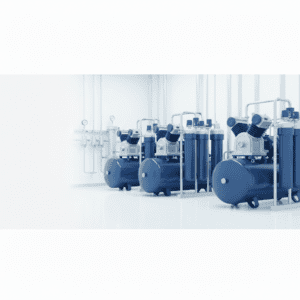

Atlas Copco Oil-Free Air Compressors for Critical Applications: Clean, Efficient, and Reliable Compressed Air Solutions

In industries where air quality is crucial, Atlas Copco oil-free air compressors provide a trusted solution. These compressors use advanced technology to deliver clean, efficient, and contamination-free air, making them perfect for critical sectors like food processing and pharmaceuticals. This article covers the technology behind oil-free compressors, key industry standards,

How to Choose the Right Industrial Air Compressor Model

Choosing the right industrial air compressor starts with your application, not the machine. Below is short, practical content aligned with CED Compressed Air’s tone and Atlas Copco product focus. Start with your application Before you look at models, get clear on how you use compressed air. Ask yourself: What tools

Essential Vibration Checks for Vacuum Blowers in Freezing Ontario Temps.

As winter descends upon Ontario, the challenges of maintaining industrial equipment like vacuum blowers become increasingly pronounced. This article delves into essential vibration checks that can prevent costly downtime during the harsh winter months. Readers will learn about the causes of vibration in vacuum blowers, how to perform critical checks,

Offsite Air Compressor Monitoring & Predictive Maintenance

Offsite air compressor monitoring and predictive maintenance are essential strategies for enhancing industrial performance. These innovative approaches leverage technology to ensure that air compressors operate efficiently, reducing downtime and maintenance costs. In this article, we will explore the mechanisms behind offsite monitoring, the benefits of predictive maintenance, and how these

Replacing Desiccant in Air Dryers: Essential Guide for Industrial Air Dryer Maintenance in Ontario

Desiccant air dryers remove moisture from compressed air by adsorbing water vapor onto porous media, producing a low pressure dew point that protects downstream equipment and product quality. Understanding when and why to replace desiccant is essential because saturated or contaminated desiccant degrades dew point performance, increases corrosion risk and

Why Energy Audits Matter for Reducing Compressor Expenses

An energy audit for compressed-air systems is a targeted inspection that finds waste, quantifies usage, and recommends measures to reduce operating costs and improve reliability. By mapping energy flows and measuring baseline kW and flow, an audit reveals where leaks, excess pressure, or control inefficiencies drive up compressor energy consumption.